The global market for submersible sewage pumps, a cornerstone of modern wastewater management, is on a path of resilient growth, shaped by urbanization, infrastructure imperatives, and environmental m...

READ MOREAbout OUMAN

OUMAN Mechanical & Electrical Co., Ltd.

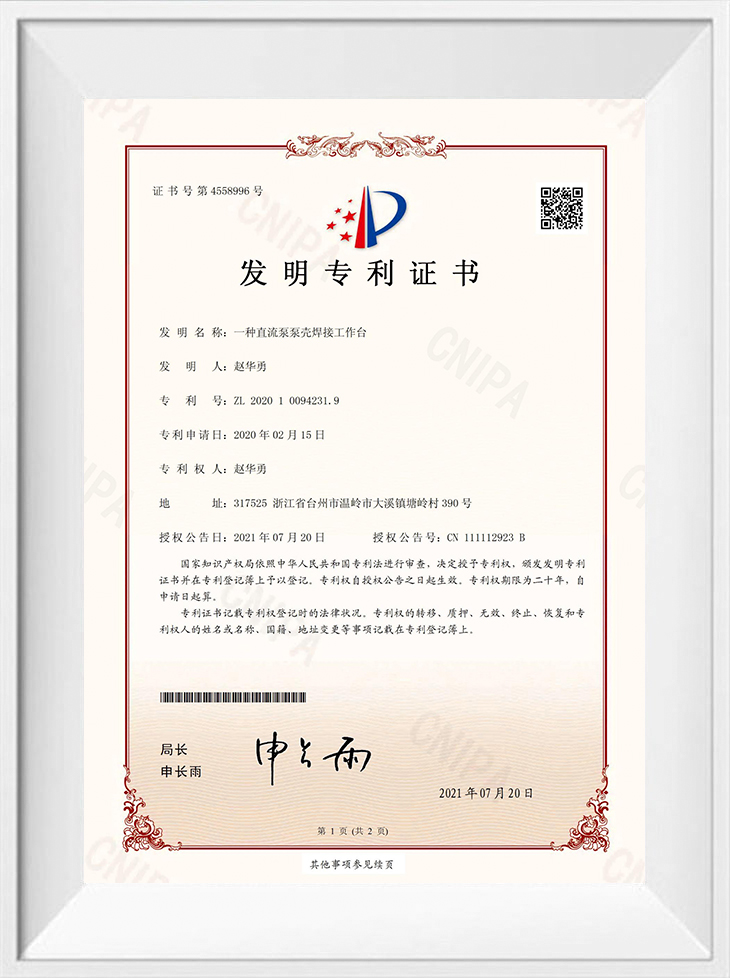

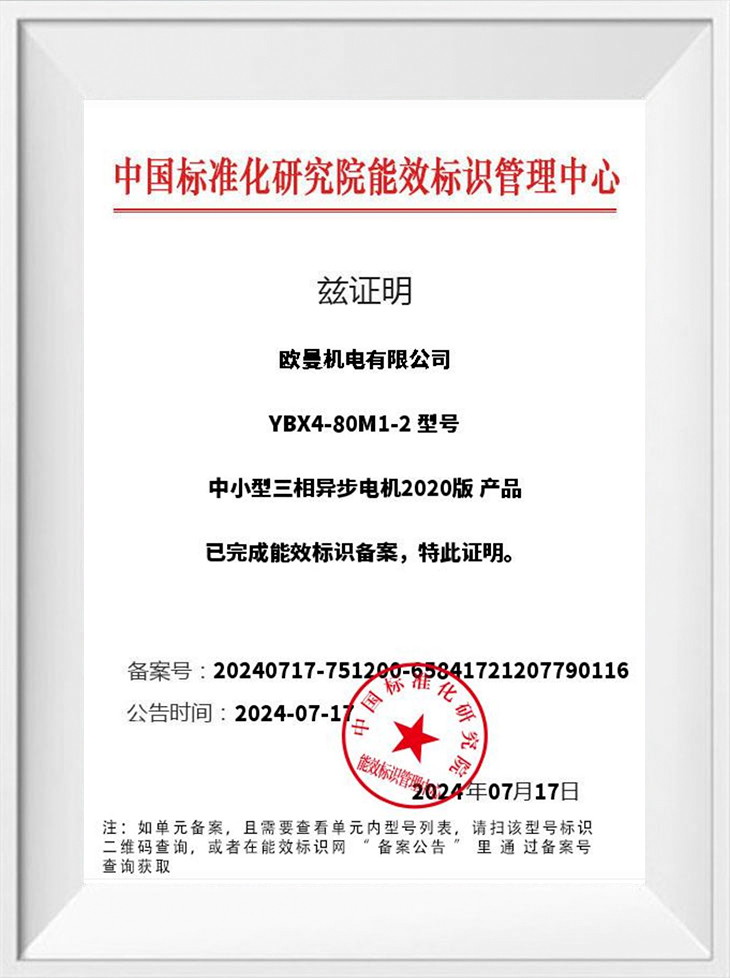

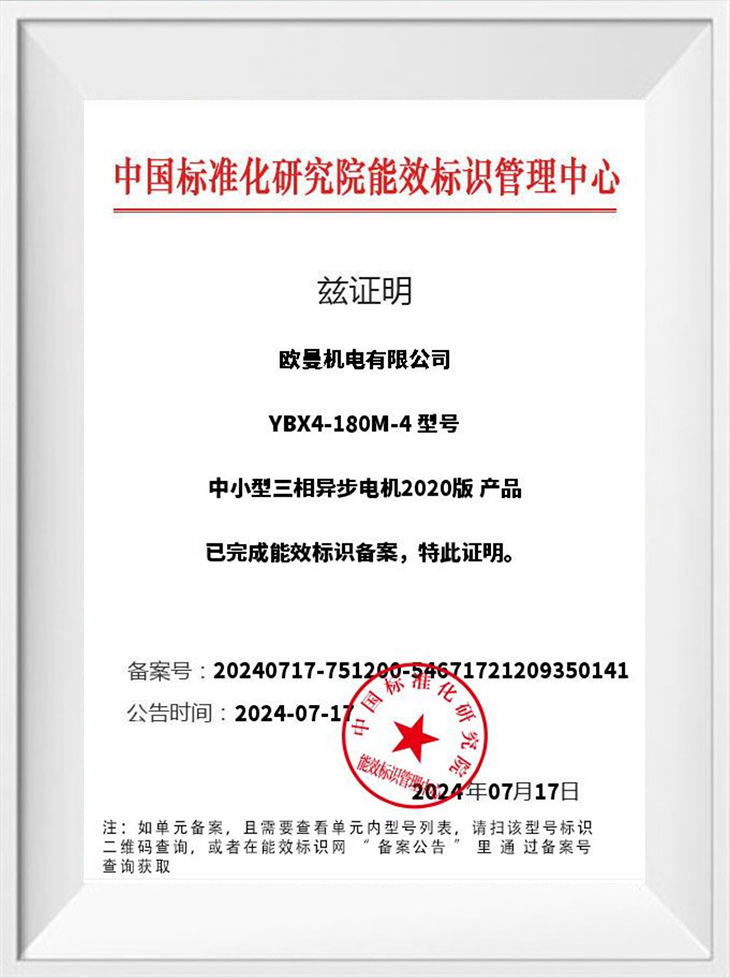

OUMAN Mechanical & Electrical Co., Ltd., an enterprise deeply rooted in the pump industry and committed to technological innovation and quality excellence, has firmly established in its corporate culture profound respect for the industry, relentless pursuit of technology, strict quality control, and active commitment to social responsibility.

Our company produces China Water Pump Control Cabinet manufacturer and sales Water Pump Control Cabinet factory with 20 major series and over 3,000 specifications. making it a professional enterprise that integrates development, production, sales, and service. Our products are widely used in industrial, agricultural, municipal, construction, water conservancy electricity, petrochemical, fire protection, and gardening.

With technological innovation, the company customizes personalized pump and system solutions for global users, helping governments and corporate clients achieve green transformation and promoting high-quality economic growth and sustainable social development.

Newsroom

-

-

The stainless steel submersible pump, a critical component in modern sanitation infrastructure, is undergoing a significant transformation. Moving beyond its traditional role as a simple mechanical wo...

READ MORE -

In the unseen networks beneath our homes and cities, a critical class of equipment operates tirelessly to maintain public health and prevent property damage: the sewage pump. These specialized devices...

READ MORE -

In the vital sectors of agriculture, construction, municipal water management, and residential life, a silent and powerful workhorse operates beneath the surface: the submersible pump. This specialize...

READ MORE

Message Feedback

English

English русский

русский عربى

عربى