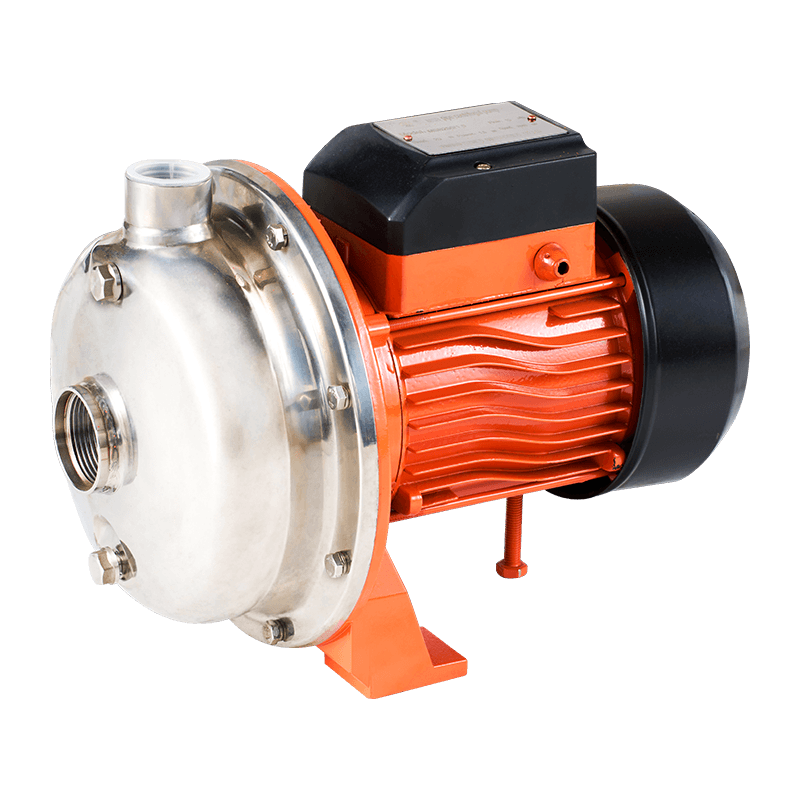

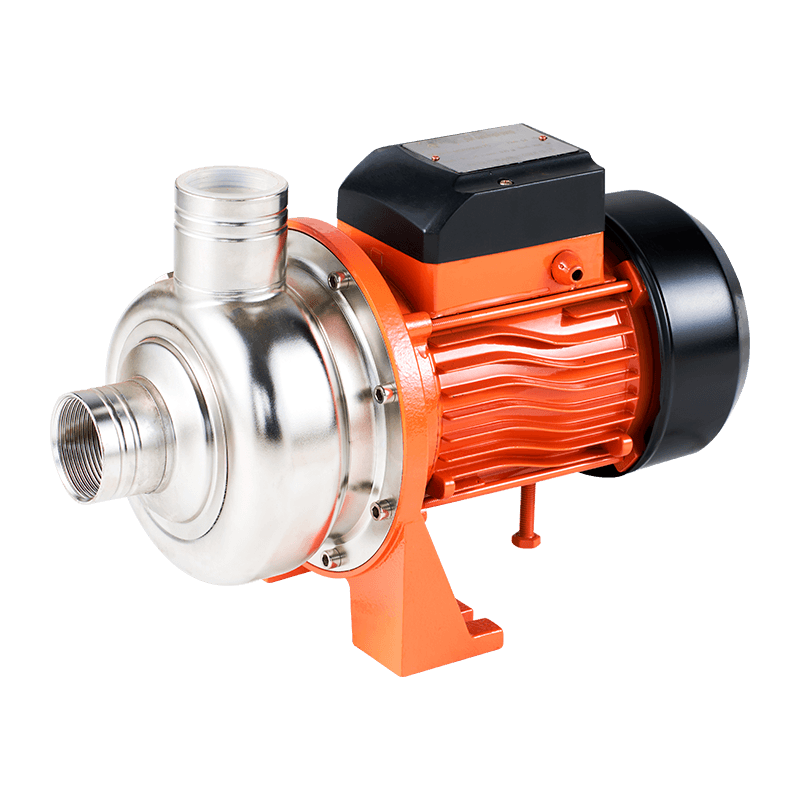

The Stainless Steel Multistage Centrifugal Pump is a high-performance pump designed for applications that require high pressure and continuous fluid movement. It is known for its durability, efficiency, and versatility, making it an ideal choice in various industries. This pump uses multiple impellers arranged in stages to increase the pressure of the fluid being pumped.

Advantages

Corrosion Resistance

One of the standout advantages of the stainless steel multistage centrifugal pump is its exceptional resistance to corrosion. Stainless steel construction ensures that the pump can withstand exposure to water, chemicals, and other corrosive substances. This is particularly important in industries where the pump may come into contact with aggressive liquids, such as chemicals, seawater, or wastewater. The corrosion-resistant nature of the pump reduces maintenance costs and prolongs its operational life.

High Efficiency and Energy Saving

These pumps are designed to operate efficiently, providing high-pressure fluid transfer while minimizing energy consumption. The multistage design ensures that the pump can achieve the required pressure without excessive energy use. This makes it ideal for applications where energy efficiency is crucial, as it helps reduce operational costs over time.

Compact and Robust Design

The compact design of the stainless steel multistage centrifugal pump makes it suitable for installations in tight spaces. Despite its small footprint, it can handle large volumes of fluid, making it highly efficient in applications requiring high-pressure pumping. Additionally, its robust design ensures long-term reliability, even in harsh environments.

Long Service Life

Due to its stainless steel construction and efficient design, the multistage centrifugal pump is built to last. The high-quality materials used in its construction prevent wear and tear, even under demanding conditions. This long service life reduces the need for frequent replacements and lowers overall maintenance costs.

Versatility

The pump is capable of handling a wide range of fluids, from clean water to more viscous or corrosive liquids. Its versatility makes it a good choice for a variety of industries, as it can be used in a broad range of applications. The ability to handle both low and high-pressure applications adds to its flexibility.

Applications

Water Supply and Pressure Boosting

Stainless steel multistage centrifugal pumps are commonly used in municipal and industrial water supply systems. These pumps are ideal for boosting water pressure in systems where a consistent and high-pressure water flow is required, such as in high-rise buildings, irrigation systems, or water distribution networks. The multistage design ensures that water can be pumped to higher elevations or over longer distances.

Industrial Applications

In various industrial processes, such as cooling, circulation, and chemical processing, stainless steel multistage centrifugal pumps play a crucial role. They are used to transport chemicals, water, and other fluids across production lines or to maintain cooling systems. Their ability to handle a wide variety of fluids makes them essential in industries like pharmaceuticals, food and beverage, and chemical manufacturing.

Irrigation Systems

These pumps are widely used in agriculture to provide pressurized water for irrigation. The ability to handle high flow rates and consistent pressure makes them ideal for large-scale irrigation systems. They help ensure that crops receive adequate water, improving agricultural productivity, especially in regions with water scarcity or where surface water is not readily available.

Boiler Feed Systems

In power plants or industrial heating systems, multistage centrifugal pumps are commonly used to provide high-pressure water to boilers. These pumps ensure a steady and reliable supply of water to boilers, contributing to the generation of steam and the efficiency of the entire heating system.

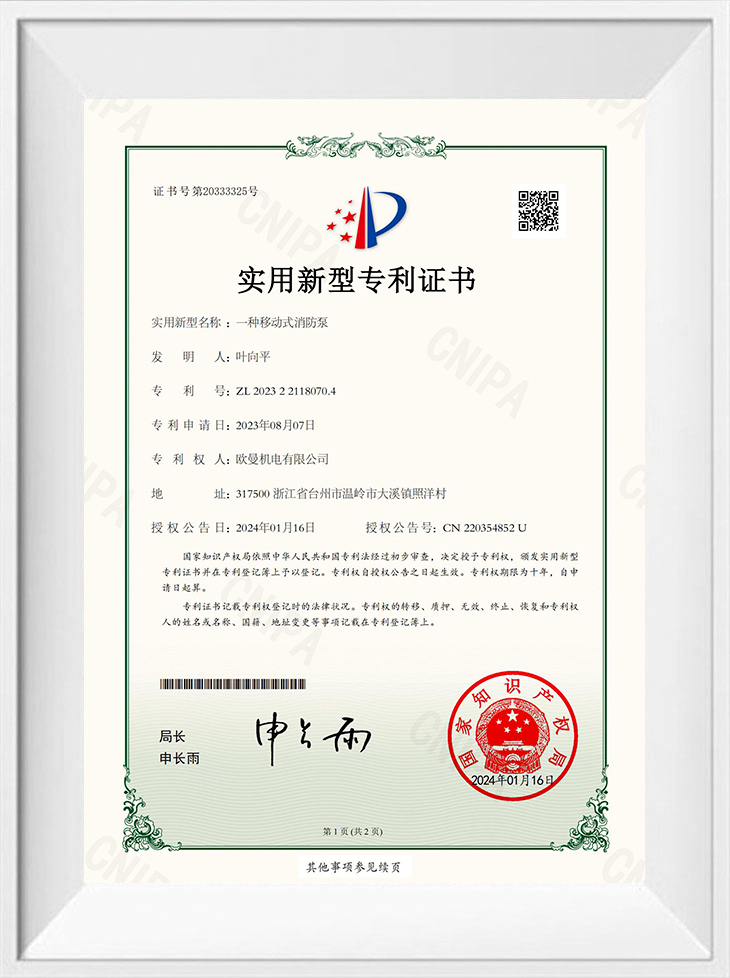

Fire Fighting Systems

Multistage centrifugal pumps are often used in firefighting systems, especially in high-rise buildings and large industrial facilities. They provide the necessary water pressure to supply fire hoses, sprinklers, and other fire suppression systems. The ability to deliver high pressure makes these pumps essential for effective fire protection.

Features

Multistage Design

The defining feature of the stainless steel multistage centrifugal pump is its multistage impeller configuration. The pump has multiple impellers arranged in series, with each stage gradually increasing the pressure of the fluid. This design allows the pump to achieve higher pressures than single-stage pumps, making it ideal for applications requiring high pressure and flow rates.

English

English русский

русский عربى

عربى